WORKING PRINCIPLE

The Paddle Wheel Flow Meter measures the flow velocity by using the fluidic to drive the blade rotation, and calculates the flow rate based on the flow velocity. ERP1 series flow meter consists of flow transmitter and pipe fitting. The light and compact design allows the user to carry, install and operate it conveniently. The product is calibrated by professional flow test device, with the accuracy of K value reaching±3%. The measuring range is 0.3 ~10m/s, with high linearity. Display and non-display type are both available. The display type is built-in with accumulated flow storage device.

FEATURES

Controlled by a microprocessor, with convenient operation and comprehensive functions. Power supply: 12-36 Vdc.

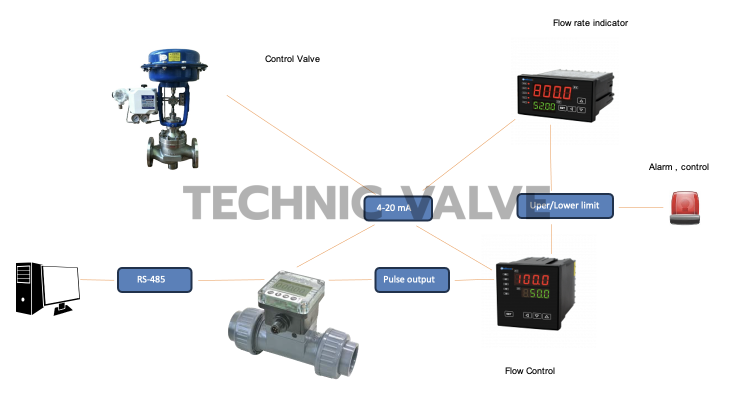

Analog output: 4-20mA with 10% higher range as 4-21.6mA Simulated test output: 0-24 mA.

Pulse output: Optical-coupling transistor output. Simulated frequency output: 0-300Hz

Pure sensing non-display type is for convenient system integration LCM (Graphic 128×64 Dots) display type

Built-in FRAM (Ferroelectric Random Access Memory) flash memory Easily separated from the sensor.

LED indicator displays the alarm status. Upper limit settings of the analog output.

Analog output flow rate and velocity filter settings: 0-40 segments. LED shows three back-lit modes, ON/OFF/In Operation.

With RS485 communication.

Parameter settings (K factor, pipe diameter, device ID, baudrate). Supports Traditional Chinese, Simplified Chinese, English, etc.

APPLICATIONS

The Paddle Wheel Flow Meter is applicable to neutral or corrosive liquids that are non-granular or non- viscous. It connects with an analog output and pulse output signal to form a monitoring system, which can display instantaneous flow and accumulated flow. Moreover, it can form a control circuit to adjust the valve or operate the switch.

※ The detected medium must not contain any iron filings, particles which will attached the rotary paddle wheel and affect the accuracy and also cause damage. If there is possibility to have iron filings, particles in the process or pump operation, please install the magnet screen filters (please consider the Pressure loss) on upstream side for the minimum distance 15 times of pipe diameter.

Food industry Beverage industry

Water treatment industry Pharmaceutical industry Dyeing industry Chemical industry

Semi-conductor industry PCB wet process control

TECHNIC VALVE CO.,LTD.

บริษัท เทคนิค วาล์ว จำกัด

About us

Tel : (66) 0-2571-4645

Fax : (66) 0-2571-3732

204/393 M.1 Chaiyapruk-Bangbuathong,

T.Pimolraj, A.Bangbuathong, Nonthaburi

11110 THAILAND.

COPYRIGHT © 2024 TECHNIC VALVE CO., LTD. All rights reserved.